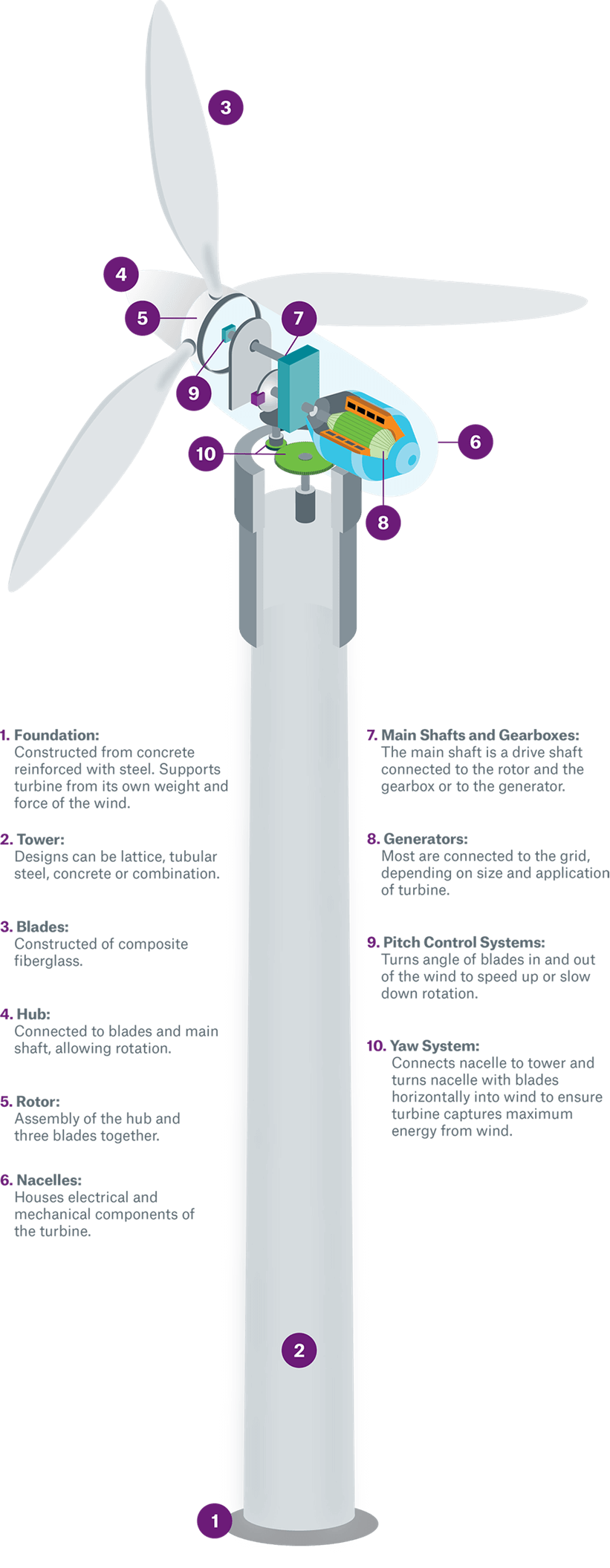

Modern wind towers are approximately 260 feet (80 meters) in height. When you are working at that distance above the ground, nothing is easy, and safety is everything. Erecting a wind tower is an engineering and construction marvel, but maintaining all of that expensive equipment once it is up in the air generating energy, and revenue, is no small task either. In today’s blog, we’ll discuss lifting solutions for maintenance and repair both from the ground to the nacelle(6) and within the nacelle itself, the cover housing that houses all of the generating components in a wind turbine.

Getting to the top of a wind tower requires strength, stamina and determination. The hike takes most workers 5-7 minutes of steady climbing, most using a “lift assist harness” that takes about 75 pounds of weight from the climber. Climbing with tools is often cumbersome and dangerous. As the nacelle is filled with moving components, otherwise known as “wear items” getting spare parts that often weigh a couple of hundreds of pounds can really be a challenge.

So, how exactly do you move repair items and tools 260 feet up in the air?

Well, there are really four methods:

• Fixed chain hoist

• Fixed electric winch

• Chain hoist on a trolley

• Electric winch on a davit crane

The first option, the fixed chain hoist is helpful in lifting heavy objects. It is simple to use, and easy to repair or maintain. A fixed chain hoist does a fine job of moving objects up and down but cannot move them horizontally across the nacelle.

The second choice, a fixed electric winch proves similar in the advantages and disadvantages of the fixed chain hoist. This option will also be helpful in moving heavy pieces of equipment and does so in an electric fashion. It proves the same challenges, in that it can move objects up and down, and not in a 360-degree rotational fashion.

A third alternative would be a chain hoist on a trolley. This keeps the advantage of having the ability to lift and lower heavy objects with the added bonus of being able to go back and forth horizontally throughout the nacelle.

The final option is the electric winch on a davit crane. This option allows the user to carry out maintenance work on windmill machinery and lift spare parts to the desired location. Allowing staff to safely raise and lower turbine appliances for repair, or replacement through the hub. The alternative to this would have been accessing the nacelle through the hatch or alongside the tower. This option allows for a compact size, long lifetime, and easy maintenance. It also allows for 360-degree rotation.

With the use of any of these applications, more work can get done in less time. This allows for reduction in fatigue, increased efficiency and improved safety within the nacelle. With the assistance of these machines, the weight of the challenge to the top gets a little lighter.

Photo Credit to Michael Roy and Equipment Connection