Thern divisions work together to provide a cost effective solution.

The Client:

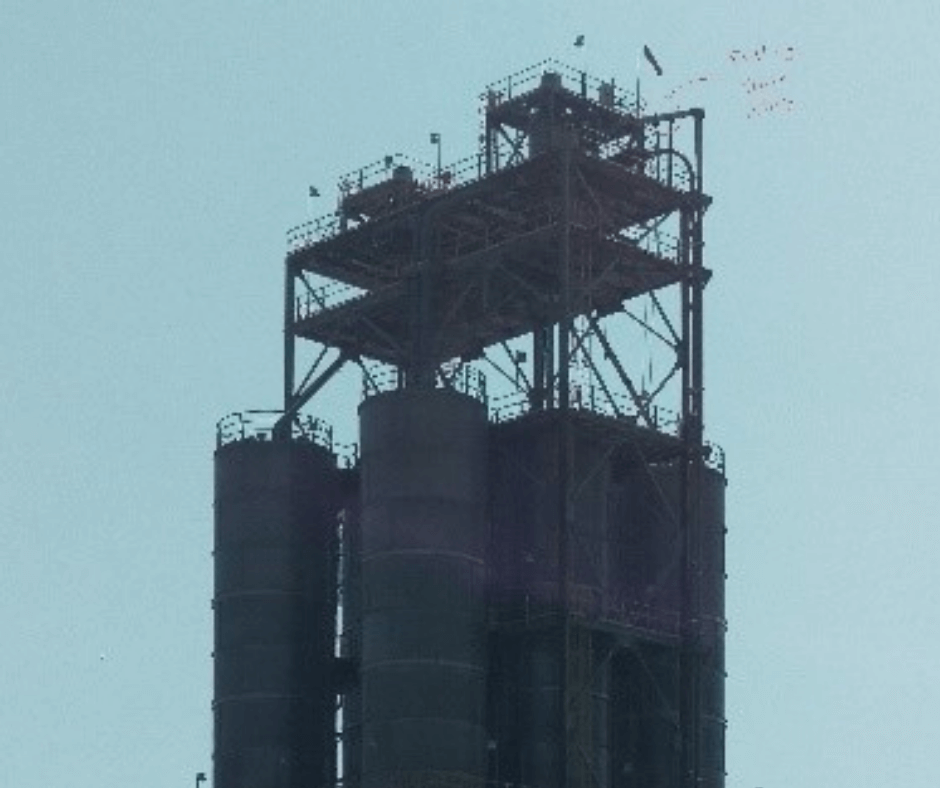

Pinnacle Polymers is a manufacturer of polypropylene pellets, based in Garyville, Louisiana. Polypropylene pellets are a common thermoplastic resin typically used for injection molding applications in various industries such as the manufacturing of person protection equipment for first respondents including those on the front line of the COVID-19 pandemic. As part of their maintenance procedures, Pinnacle Polymers must routinely service equipment installed at the top of their rail car loaders and storage silos.

The Challenge:

The maintenance regimen of Pinnacle Polymers required the use of mobile cranes to fulfill their needs, which proved to be a high expense to the company. In addition, the maintenance had to be scheduled according to the availability of the mobile cranes, making service and maintenance jobs an endeavor to accomplish. Pinnacle Polymers decided they needed a crane capable of lifting up to 270 ft while supporting a max load of 3,500 lbs., replacing the need for a mobile crane.

Thern’s Solution:

Thern built a customized davit crane to meet the requirements of Pinnacle Polymers. This crane will save up to $12,000 in construction costs in each instance the mobile crane would have been used. Together in a multi-disciplinary team, engineering, technological sales, and out-side sales all worked together to developed a cost-effective solution to meet the customer’s needs.

If you have a problem and are looking for an exceptional solution contact Thern today!