Thern’s customizable stationary davit crane ensures reliable and efficient maintenance operation procedures in petrochemical facilities.

The Client:

Pinnacle Polymers was elated with the results of a previous Thern solution, that they called Thern for their next project. They are a manufacturer of polypropylene pellets based in Garyville, Louisiana. Polypropylene pellets are a common thermoplastic resin typically used for injection molding applications in various industries, including PPE elements. As part of their maintenance procedure, Pinnacle Polymers must routinely service equipment installed at extensive heights. This is located at the top of their storage silos.

The Challenge:

The most challenging part of Pinnacle Polymer’s maintenance procedure operations was to bring heavy spare parts, components, and tools up to the top of their storage silos. They required reliable and efficient solutions for their employees to transport equipment. Pinnacle Polymers had been renting mobile cranes to fulfill their needs, which depended on the availability and the schedule of mobile cranes to perform maintenance routines. They requested a more permanent and cost-effective solution to complete this routine conveniently and safely.

Thern’s Solution: Stationary Davit Crane

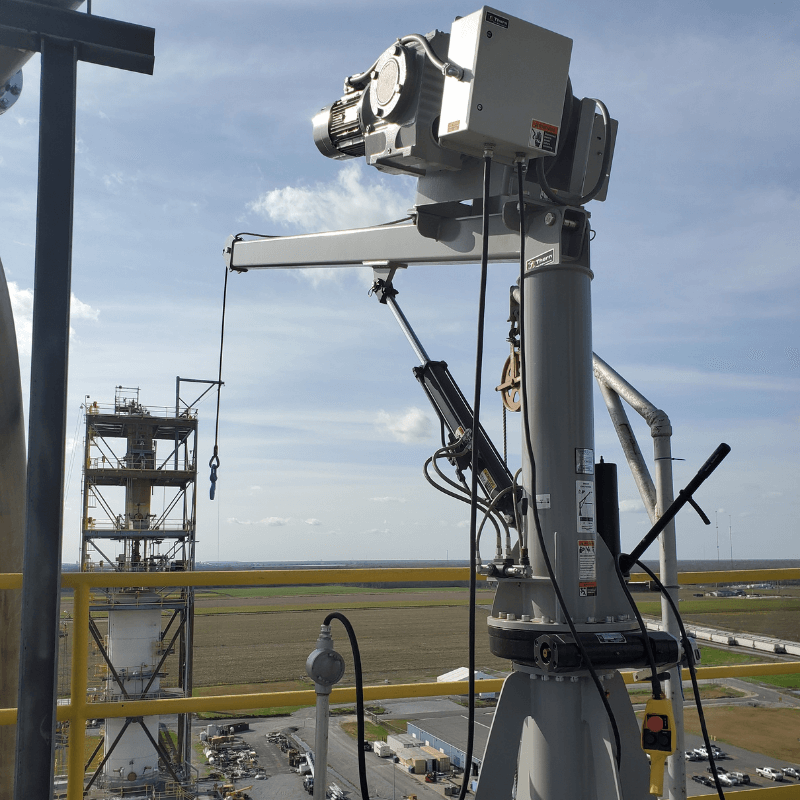

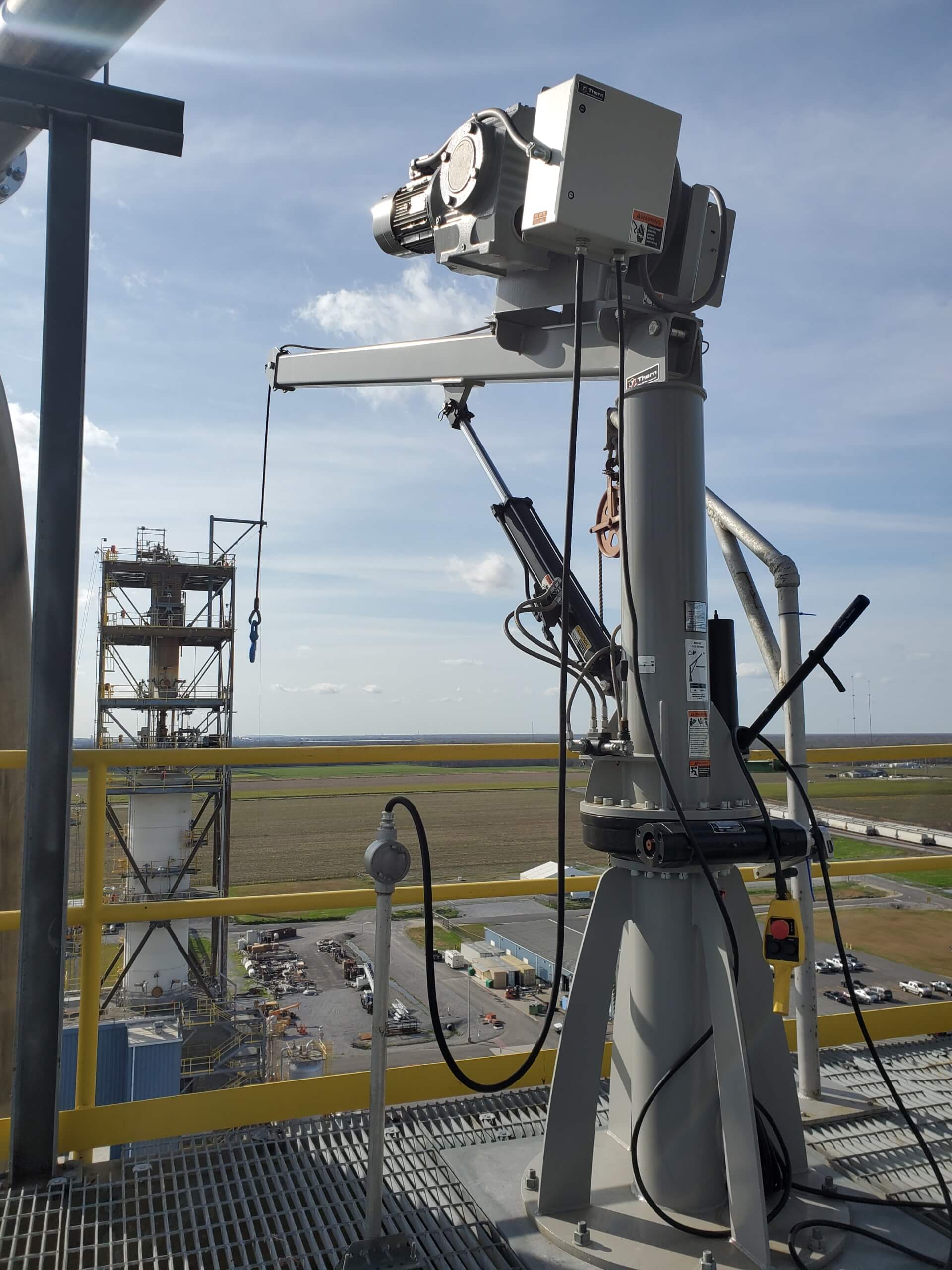

Thern’s Captain 4000 davit crane was the perfect answer for these maintenance procedures. With customizations, Pinnacle Polymer was able to create the ideal lifting and repositioning solution for them. This crane has a reach of 110 inches as well as a hook with a height of 108 inches. All while having a rating of 3,500lbs in all positions with a lift below the floor of 200 ft. With our 3Part Epoxy, we provide additional protection to the davit crane and winch in order to extend the life of the equipment installed near the coastline of Louisiana.

It was important to Pinnacle Polymers to adjust the crane’s boom angle under load, so Thern included a self-sustaining hydraulic jack system. This option doesn’t require power from an external HPU.

The cranes’ design and performance allow for a straightforward and reliable operation. It was designed to be operated by only one operator that could lift, rotate and position the load without major effort.

If you have a problem and are looking for an exceptional solution contact Thern today!