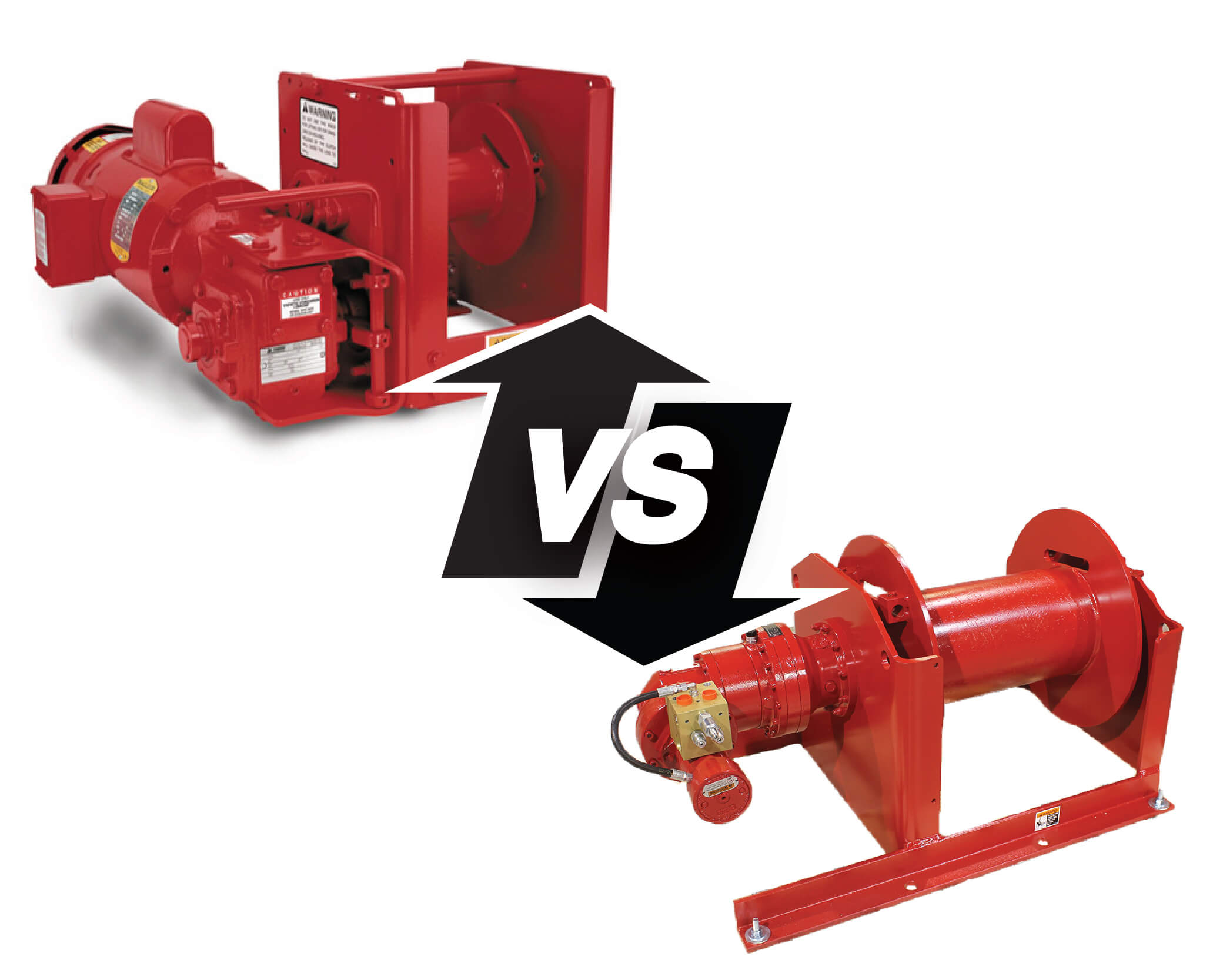

Winches are an essential product in many industries, including construction, marine, oil and gas, bulk material handling, wastewater, and theater. Depending on the application, the power source for the winch may include manual, pneumatic, electric, and hydraulic. Two of the most common power inputs are hydraulic and electric. Each provides various advantages and disadvantages for given applications. Do you know the differences between an electric winch vs. hydraulic?

Electric Winch vs. Hydraulic: A Breakdown

Electric Winches

Electric winches are made to give the end-user ultimate control. They provide long or short travel distances and can accommodate slow or fast line speed requirements…or anything in between. There are many advantages of an electric winch:

- Electric winches are reliable and efficient and can be sized to match any application with an available electrical power source.

- Electric winch operation is quiet! The need for noisy HPU is eliminated. Low noise levels aid job site communications and safety.

- Electric power is clean, eliminating the risk of hydraulic fluid leaks and environmental concern.

- They are available in a wide variety of sizes and configurations, allowing for adaptation to space constraints.

- Electric winch controls are available with a wide variety of features to tailor the product to a specific application. These options include but are not limited to:

- Single-speed reversible motor controls; variable-speed controls using VFD (variable frequency drives)

- Load travel limit switches

- Dynamic braking

- Soft start/stop of load

- Digital readout monitoring of speed and load

- Constant tension settings

Though electric winches are a solution in many applications, some disadvantages exist:

- Appropriate power for the winch might not be readily available and bringing power to the point of use can be expensive and time-consuming.

- Variable frequency drives are a more expensive option than a hydraulic pilot valve to control load movement for applications where variable speed is desirable

- Motors may need to be upsized to provide continuous or near-continuous duty

Hydraulic Winches

Hydraulic winches are commonly utilized in mining, offshore oil/gas, and construction-type applications. They are often the best choice because:

- Electric power is not available–commonly shipboard or other mobile applications.

- A hydraulic power unit (HPU) is readily available.

- Variable speed rope/load control is desired, without the addition of costly VFD (variable frequency drive) controls.

- Site conditions are deemed hazardous due to explosive atmosphere (gas or dust).

- An electrician is not required for installation.

- Continuous duty cycles may cause performance degradation in electric units due to overheating.

While a hydraulic winch may be the solution in some applications, there are also some disadvantages:

- Hydraulic winches require a hydraulic power source which may not be available.

- Hydraulic power carries the risk of hydraulic fluid leaks and/or sprays.

Now you know the main differences between an electric winch vs. hydraulic.

Regardless of your application, the experts at Thern can help you select the best solution. With a wide range of “off the shelf” solutions and modular designs that allow for cost-effective and rapid customization, a safer, more productive work environment is a phone call or an email away!