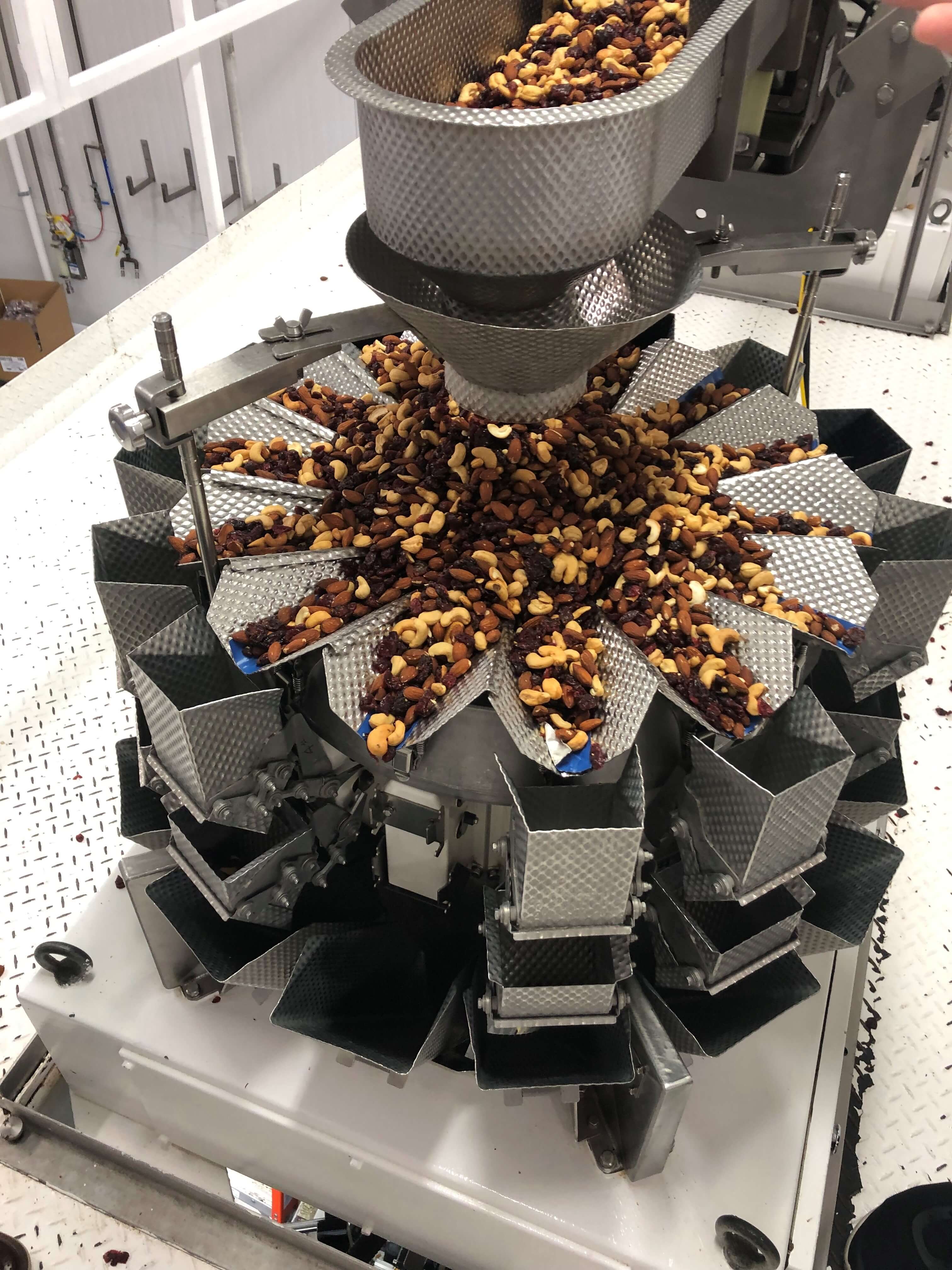

Torn and Glasser, founded in 1928, has been a family-owned business for over 85 years, passed down three generations. The business began growing walnuts and watermelons, marketing their fresh produce in Los Angeles, California. They have since expanded their wholesale produce line and now import, process and package nuts, dried fruit, beans, rice, spices, candies and grains. Like Thern, Torn and Glasser offer custom and personalized services for their customers, taking great pride in paying attention to detail and delivering the perfect product for their customers.

With the help of CableCo, Torn and Glasser acquired several stainless steel First Mate davit cranes to be implemented in their food processing plant in Pomona, California. The stainless steel finish was a great fit for this application, as it is neutral to food and easy to clean. The davit cranes were installed on top of mezzanines in the plant to assist in transporting products up and down. Specifically, the crane offered an easier and safer way to transport custom made trays that are part of their automated food packing system. These custom-built trays are only manufactured by one vendor, based out of Japan, with each tray costing around $1,000. Before the installation of the First Mate, employees carried these trays up and down steep steps connected to the mezzanine for daily cleaning. It was not uncommon for workers to drop and damage these fragile, custom made trays on the stairs, costing the company thousands of dollars to replace.

Now, with the implementation of Thern’s First Mate davit crane, equipped with an easy-to-use electric winch system, these expensive trays are transported up and down the mezzanine with the touch of a button. This installation not only offers an easier and safer way of transporting the trays but also eliminates a once stressful task for Torn and Glasser employees.

Do you have a problem, but can’t figure out a solution? Thern will happily take on any challenging applications using standard or custom made winches and products to solve your problem. Contact Thern today, let us take the weight off your shoulders.