Industrial winches and hoists are designed to move many types of loads. Both of these mechanical devices are the same in a number of ways. They can be manual (hand-powered), electric, pneumatic, or hydraulic. But some applications are simply better with a winch while others should only employ a hoist. When should you discriminate against one and show preference to the other? This article will help clarify that for you.

What’s the Difference?

Before going over which applications are a better fit for either a winch or a hoist. Let’s first look at the main similarities and differences between these two types of material handling equipment.

Industrial Winch:

A winch is a device that can move many different loads with the use of a rope that is anchored to the winch’s drum or drum flange on one end and connected to the load on the other end. Most industrial winches use wire rope but many can also use a synthetic rope. When the drum turns, the rope is spooled onto the drum (unspooled if drum rotation is reversed) and the tension created or released moves the attached load.

Wire rope with swaged ball end anchored in winch’s drum flange:

Industrial Hoist:

An industrial hoist is also a tool that is used to move various types of loads. The term “hoist” however is a bit more subject to interpretation by some and occasionally causes confusion. Unlike a winch that can be used to either pull (horizontal load travel) or lift (vertical load travel), a hoist is only used for vertical lifting applications. Since hoists are exclusively utilized for lifting, they’re often automatically referred to lifting devices as hoists; sometimes this includes winches that are used as lifting devices. It is not uncommon for winches to be referred to and used as hoists often phrased as – winches doubling as hoists.

Are winches safe to be used as hoists? Absolutely! As long as the winch is equipped properly for the intended move, it can safely lift or lower loads. More on that later.

A couple more comparisons – As mentioned earlier, industrial winches use either wire or synthetic rope. Some hoists also use wire rope, but hoists are most commonly used with a chain. Hoists that use wire rope have drums like winches do but unlike winches that exclusively use drums, many hoists use lift-wheels rather than drums to create tension to move their load.

To hoist, or not to hoist.

When should you use a hoist and when should you use a winch? There are many variables to consider in determining the best lifting/pulling equipment for a specific project but there are just a handful of key factors to keep in mind to help you determine whether you should lean towards a hoist or an industrial winch.

*Direction of load travel

By definition, to hoist something literally means to lift something. Hoists are synonymous with vertical lifting applications because they are designed to be used only in jobs where the load exclusively travels up and down. In contrast, a winch can be used to pull horizontally, lift vertically acting as a hoist, and everything in between. Including pulling at an incline (not completely horizontal) where the load can run if tension is released. This requires the winch to have a secure type of braking system, explained in the next key factor below.

*Braking safety

When an application calls for lifting or pulling at an incline, it is safer to obtain a device that has a mechanical brake. Dynamic braking systems should not be relied on when doing these types of moves. A dynamic braking system uses gears to slow a move or hold the load in place. This is only acceptable for completely horizontal or flat pulls when the load will not run if the gears give way, and the tension is released unintentionally.

Hoists usually have a mechanical braking system to safely lift or lower their load. Hoists however are not the only ones that can be configured with mechanical brakes. Many winches are known to use dynamic brakes, but quality winches that are designed to lift or pull at an incline will also have mechanical braking systems to make their moves secure. Thern’s industrial winches for lifting and pulling at an incline all come with mechanical brake systems. For added security, various optional secondary braking systems are available. Winches with worm gearing to prevent back-driving when the tension is released are also available.

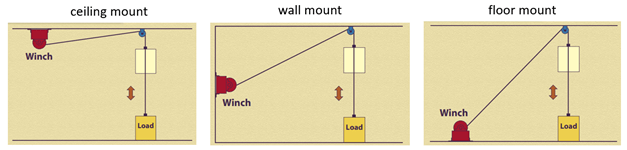

*Positioning

Hoists are normally positioned right on top of the load either permanently or on a moving assembly like a trolly on an overhead crane. Most industrial winches can be mounted on the floor, wall, ceiling, or above the load. Winches are also commonly used with sheaves that can change the direction of the rope. You have much more flexibility in positioning a winch at a location that best fits your project.

*Footprint

If space is a big consideration, a hoist will likely be a better solution than a winch. You need to account for the size of the drum and the overall footprint of the winch, usually larger than a traditional hoist.

*Distance of load travel

Since winches use rope and hoist commonly use chain, winches are better for long-distance while hoists are better for short vertical lifts. For applications like rooftop lifting when covering tens or hundreds of feet in distance, working with ropes is more manageable and lightweight. Wire rope simply makes more sense than working with chain in this setting.

For shorter and frequent lifts like at a factory floor, chain hoists are usually better because they can be easily mounted on trolleys on overhead cranes that are commonly found in factories.

So, are industrial winches and hoists created equal?

No, they are not. Hopefully, the information here can help you determine which one to employ for your next pulling or lifting job.

More to come on Industrial Winches and Cranes.

Thern has been proudly designing and making top-quality material handling equipment like industrial winches and davit cranes since the post-World War II boom. Thern’s reliable equipment has been used in countless different applications for decades! Customers rely on our expertise to help with their pulling and lifting projects.

Keep an eye of for articles like this one to address these recently requested topics.

Contributed by Jay Atienza, Industrial Market Manager