Electric winches are the driving force in lifting, lowering, or pulling; they keep your operation running. But even the best equipment can experience hiccups over time. The good news? Many common winch issues can be diagnosed and resolved with a little knowledge and the right resources.

In this blog post, we’ll walk through frequent challenges users face with portable electric winches like the Thern 4WP Series and 477 Series and offer tips to get back up and running fast.

Why is my Thern electric winch not braking properly?

First, ensure your wire rope is installed correctly. Most winches are directional; therefore, improper wire rope installation will result in performance issues and damage if not corrected. In most situations, it is necessary to install the rope so that it is underwound on the drum.

Thern Parts & Service Tip: Always maintain the required number of Anchor Wraps.

Ensure sufficient tension on the Rope during installation.

Why is my Thern electric winch leaking oil?

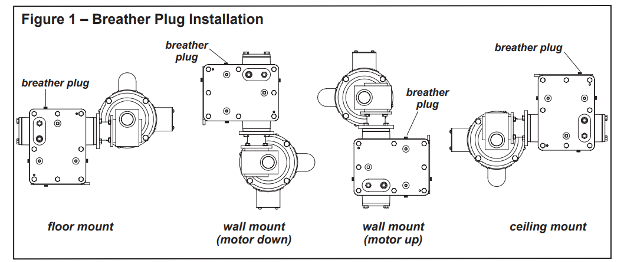

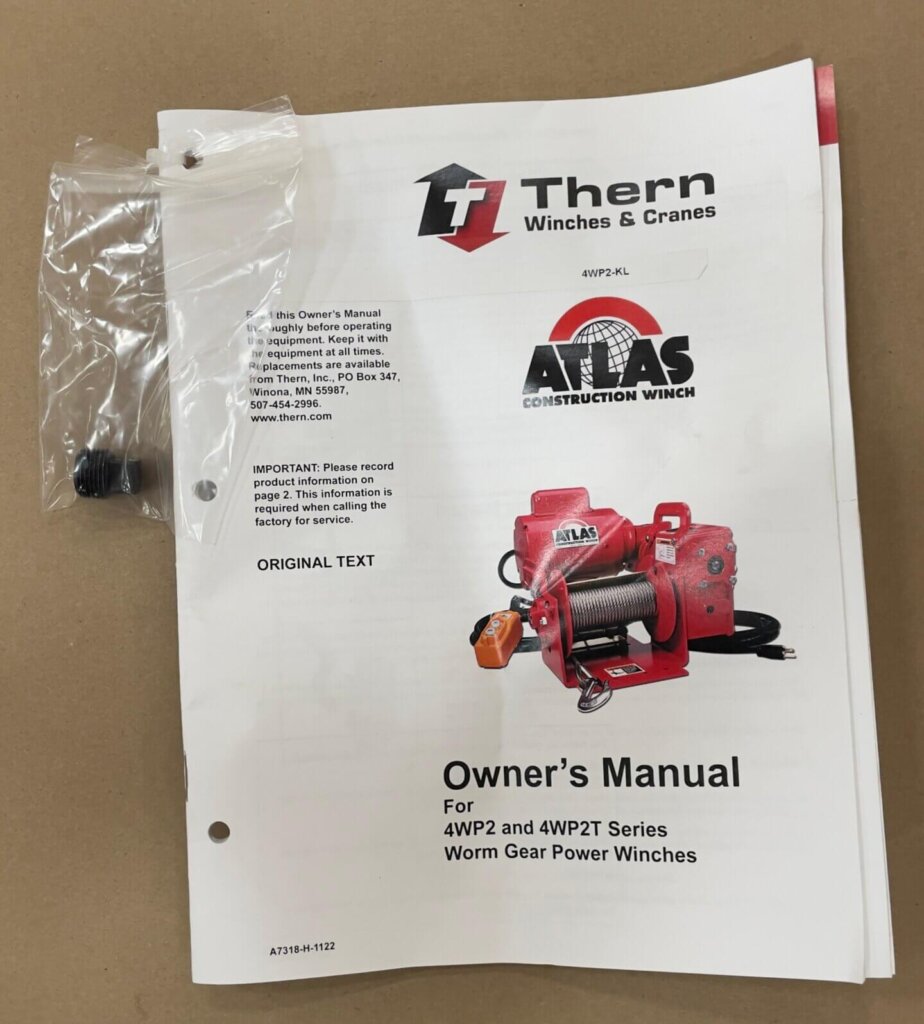

Many users overlook a small—but—crucial installation step: the breather plug. Thern winches are shipped filled with oil and sealed, with the breather plug in the box (not installed). If you forget to install it, pressure can build up inside the gearbox during use, potentially damaging seals and leading to leaks.

Thern Parts & Service Tip: Always install the breather plug before operation. You’ll find it in the packaging attached to the owner’s manual, swap it with the corresponding oil plug, based on the winch orientation, before use.

IMPORTANT: Save the oil plug to use when the winch is removed for storage or transport. Before using your electric winch, check the oil level in the gearbox to make sure no oil was lost during shipment.

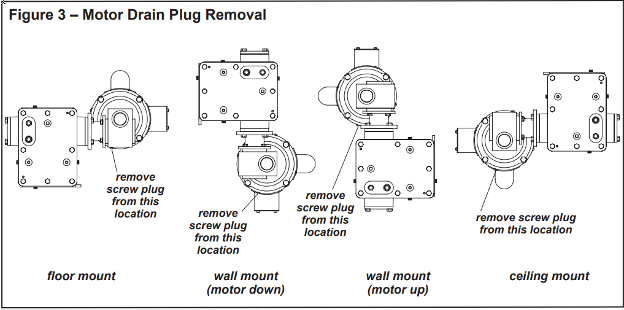

Electric Winch Motor Drain Plug

Most motors are designed with drain holes to allow the passage of water, preventing it from accumulating within the motor housing. This is an important feature, as excess moisture can lead to corrosion and damage over time.

When it comes to determining which plug to remove for drainage, it is essential to consider the orientation of the motor. Different motors may have varying designs, and the location of the drain hole can differ based on whether the motor is mounted vertically, horizontally, or at another angle.

By identifying the correct plug based on the motor’s orientation, you can ensure that any trapped water is effectively drained out, thus maintaining the motor’s efficiency and longevity. Always refer to the user’s manual for specific instructions regarding your motor model, as this will provide the best information on proper maintenance and drainage procedures. An example is shown below.

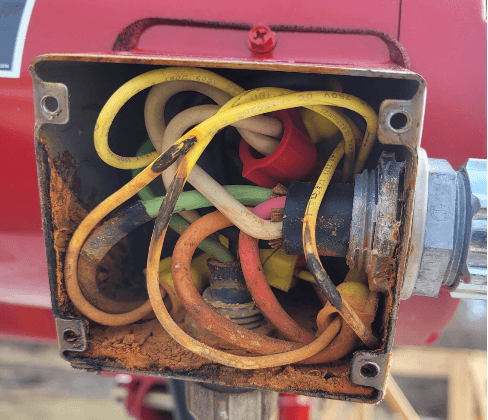

Electric Winch Junction Box

Another vulnerable area often overlooked is the junction box, where electrical connections are housed and sealed.

The junction box is equipped with a gasket designed to seal the enclosure where the wires connect. If this gasket is crooked or twisted, has dirt or debris beneath it, isn’t properly compressed during reassembly, or wasn’t reinstalled at all after the wiring, it will not create a watertight seal. This can allow moisture to enter over time, leading to corrosion of the terminals, reduced electrical performance, and potentially complete winch failure.

Thern Parts & Service Tip: Whenever you’re servicing or wiring an electric winch, always double-check gasket placement and compression. It’s a small step that can prevent major downtime.

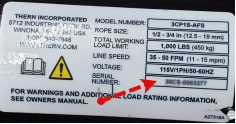

Power Problems: Electric Winch Won’t Start

If your electric winch is not running, check for the following issues prior to hopping on a call with your Thern service rep:

- Inadequate voltage or incompatible power supply.

- Tripped breakers or blown fuses.

- Faulty pendant controls or damaged cords.

Thern Parts & Service Tip: Confirm the voltage matches your winch model and inspect connections for damage. Don’t forget to check the control pendant and power source.

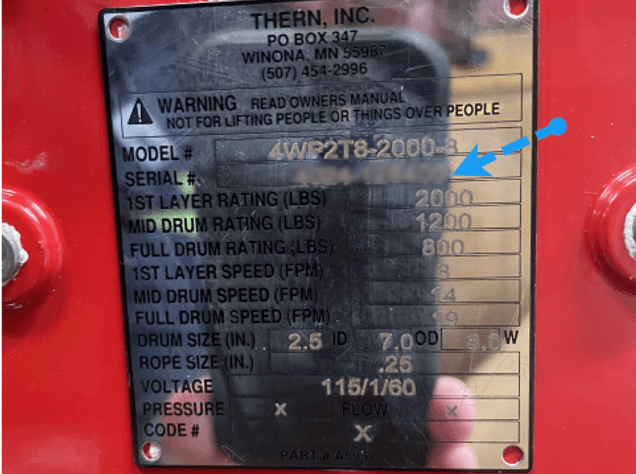

The Importance of the Serial Number

Before you begin any return or repair, please locate your serial number, which can be found on the metal tag of your winch. This number will help our Parts & Service team provide you with swift support.

Approximately half of Thern’s products are customized in some way, and the serial number is linked to the original order and bill of materials. This allows our team to identify any variations or customizations, preventing fitment issues and reducing downtime.

Thern Parts & Service Tip: Serial numbers allow verification of warranty status.

Submitting a Returned Goods Authorization Request

Lastly, if your troubleshooting leads to a repair, follow our Returned Goods Authorization (RGA) process:

- Email our Parts & Service team at [email protected].

- Include the product serial number.

- Describe the issue and attach any photos or videos.

- Our team will evaluate and issue instructions for the next steps through email or phone.

Did You Know?

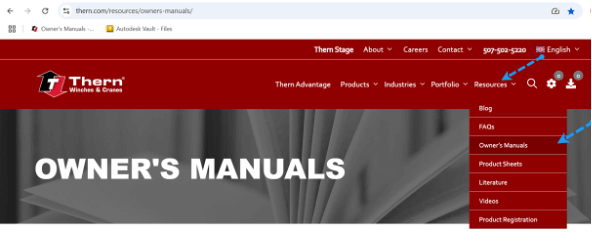

Thern offers a two-year warranty on all winch products. Additionally, our manuals, available online, include complete troubleshooting charts, maintenance checklists, and specifications to help you resolve issues fast.

Questions on the 2-year Warranty Period?

All Thern Warranty period is based on:

- Date of purchase by end user, provided the user has proof of purchase.

- Date sold by Thern.

Manufacturer’s Warranty Covers:

- Defects in material or workmanship.

Does Not Cover:

- Damage due to accident, alteration, misuse, abuse, or negligence.

- Wearable Components such as brake discs, wire rope, etc.

Need Help Right Now?

We’re here for you. Whether you have a quick question or need detailed guidance, Thern’s technical team has your back.

Explore our support resources on our website or contact us today.