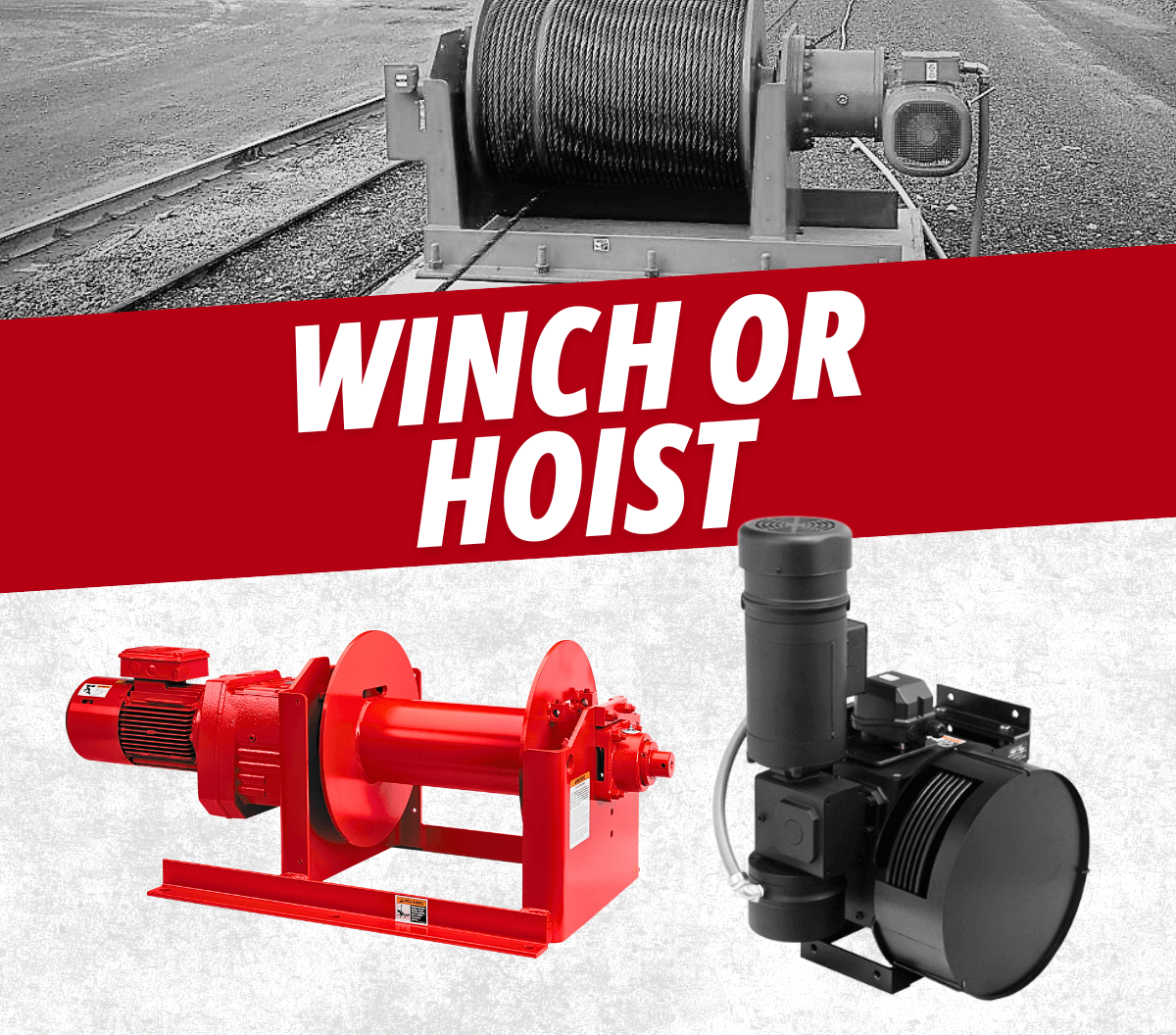

Choosing between a winch and a hoist can directly impact the safety, efficiency, and success of your operations. Whether you’re pulling railcars or raising stage equipment at an arena, making the right decision matters. In this post, we’ll break down the core differences between winches and hoists, explore their ideal applications, and show how Thern delivers tailored solutions across both industrial and entertainment industries.

What’s the Difference Between a Winch and a Hoist?

Both winches and hoists are designed to move heavy loads, but their functions and strengths differ.

Winches handle both horizontal pulls and vertical lifts. These versatile tools are used to pull heavy materials in construction, marine operations, and industrial applications. Thern’s winches are engineered for durability and can include options like electric, air, manual, or hydraulic systems to fit a range of needs.

Hoists specialize in vertical lifting and are essential for applications where secure overhead positioning is required. They’re especially common in environments like factory floors, theaters, or other entertainment venues. Thern Stage Equipment offers specifically designed hoists that handle everything from lighting rigs to large scenic elements.

Winches: Power, Precision, and Versatility

Winches are designed to handle a wide range of load movements, including pulling, lifting, and positioning tasks, making them a more flexible choice. Thern’s diverse range of winches includes:

- Electric Winches: Perfect for long-distance lifts and faster line speeds, handling loads of up to 100,000 lbs. These winches are ideal for industries like construction and bulk material handling.

- Portable Electric Winches: Lightweight but powerful, these winches can handle up to 4,600 lbs. Their portability makes them ideal for job sites where versatility is critical.

- Manual Hand Winches: Dependable for environments without power access, with options to lift up to 4,600 lbs using durable worm and spur gear designs.

- Air Winches: Capable of lifting up to 10 tons, air winches provide rugged reliability for industrial applications with demanding safety requirements.

- Hydraulic Winches: Built for dynamic projects, these winches feature custom control options like remote operation, slack line detection, and load-limiting capabilities.

Explore Thern’s full range of industrial winches here.

Hoists: Built for Vertical Lifting

Hoists are built for swift, controlled, repetitive lifting while reducing manual labor and operational delays. Thern Stage Equipment specializes in hoists designed for both traditional theaters and large arenas. Learn more about Thern Stage Equipment hoist offerings here.

Case in Action: At U.S. Bank Stadium, custom line shaft hoists manage retractable bleachers, helping the venue support diverse events easily.

“We first determine what type of venue our client has. Entertainment or industrial? If the application involves lifting over people, we communicate with our expert theater team to assess and assist.” – Jeff Wilkowski, Senior Applications Engineer at Thern

Customization and Control Systems

Every operation is unique, and Thern delivers tailored solutions to meet those specific needs. Our control systems allow operators to lift, and position loads safely and efficiently.

Customizable electric winch control systems include single-speed, variable-speed, and remote-control options, built with high-quality UL components.

Winch or Hoist—Which Is Right for You?

Choosing the right tool comes down to your unique requirements for your application. Winches excel in horizontal pulling and long-distance vertical lifting, while hoists are built for frequent overhead vertical lifting and lowering.

Thern offers durable, customizable solutions trusted by industries worldwide.

Still wondering whether a winch or hoist is right for you? Let’s find the perfect solution together—reach out to our team today!

If you enjoyed this post, you may also like Top Advantages of a Construction Winch on the Jobsite