Barge positioning is the process of aligning a barge for loading, unloading, or securing in ports, terminals, and waterways. This ensures the efficient handling of bulk materials like grain, coal, or sand while maintaining safety and minimizing downtime.

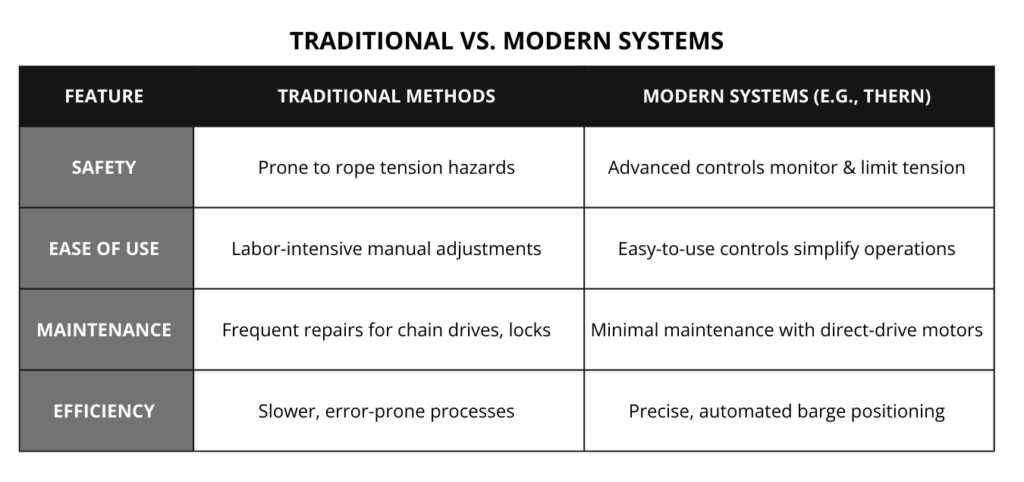

For decades, many operations relied on traditional methods—ropes, chain drives, or basic winches. While effective in their time, these methods often come with challenges: safety risks, inefficiencies, and high maintenance demands.

Modern systems address these issues with advanced controls, direct-drive technology, and automation. These innovations aren’t just upgrades—they’re essential for safer, more efficient operations.

How do traditional methods compare to modern systems? Let’s explore the key differences to help you decide what’s right for your operation.

Traditional Barge Positioning

Traditional barge positioning systems rely on manual effort or outdated designs. While they’ve served their purpose in the past, they come with serious limitations:

- Safety Risks: Without advanced controls, excessive rope tension can lead to equipment failure—or worse, accidents that endanger workers.

- Labor-Intensive: Manual systems require constant operator oversight, leading to fatigue and inefficiency.

- High Maintenance: Chain drives, ratchet-dog locks, and other outdated components demand frequent repairs, adding to downtime and costs.

Additional Legacy Methods

- Drag Brakes: Legacy systems utilize drag brakes to control the movement of the barge. One winch pulls while the other employs a drag brake to create tension in the trailing winch. This setup adds to maintenance costs and requires frequent adjustments to prevent the barge from drifting away from the dock.

- Capstan Winches: Another legacy style positioning system, capstan winches, rely on manned lines and mechanical advantage to move barges into position. These systems, while functional, are ergonomically challenging to modern barge positioning systems.

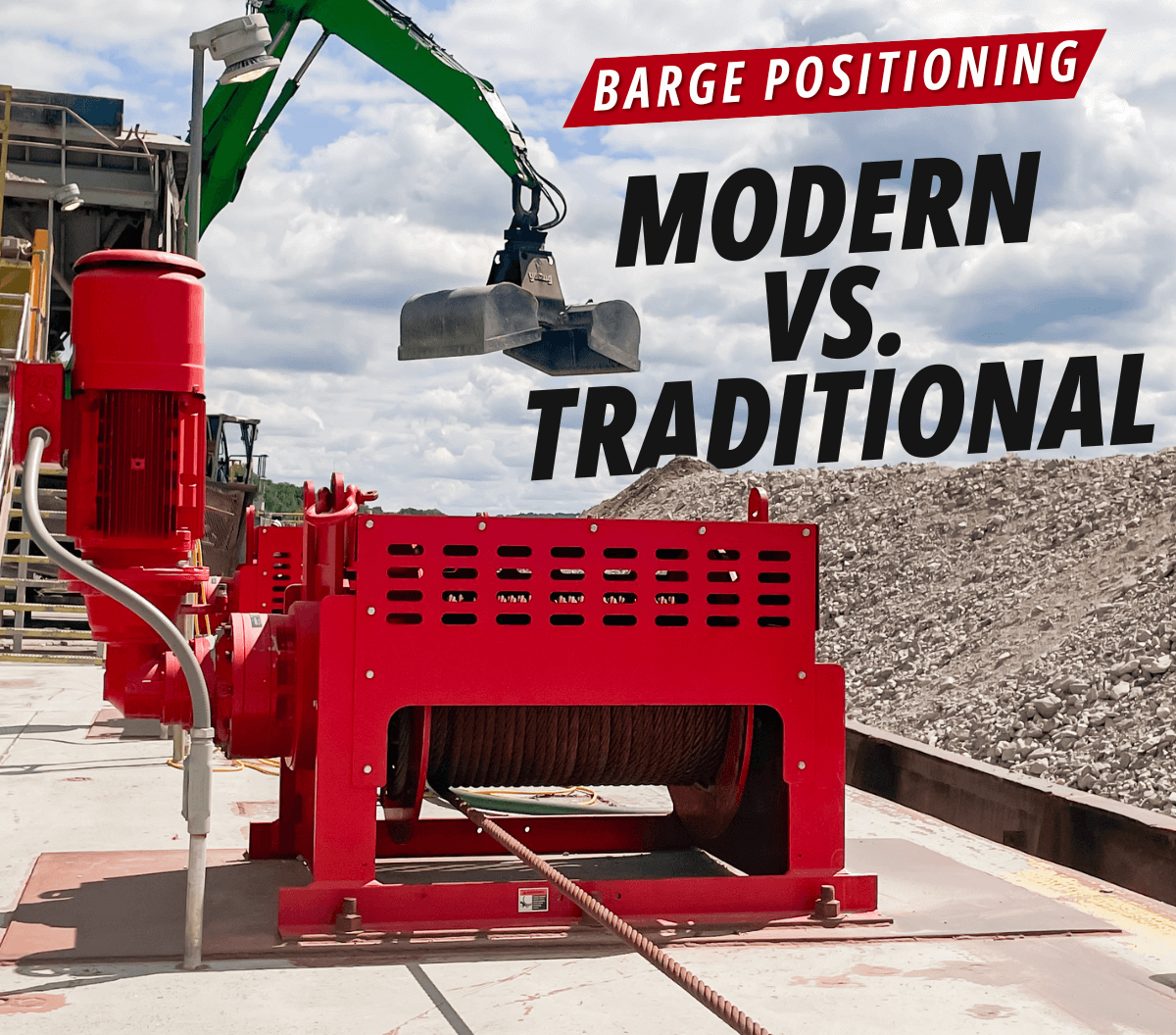

Modern Barge Positioning Systems

Modern systems, like Thern’s barge positioning winches, are designed to address these challenges head-on:

- Safety First: Advanced, yet easy-to-use, controls monitor rope tension and prevent hazardous scenarios, eliminating risks like sudden breakage.

- Efficient Operations: Automated features and remote-controlled winches allow operators to position barges with precision and minimal effort.

- Low Maintenance: Direct-drive motors eliminate chain drives and couplings, reducing wear and tear for a nearly maintenance-free experience.

- Seasonal Adaptability: Rivers have various aspects to consider for barge positioning, depending on the time of year. They run high and fast in the spring and early summer, while in the fall, and during droughts, they’re low and slow. Thern’s advanced controls allow operators to easily adapt to changing flow rates and river/tidal levels.

“Many of our customers are moving bulk materials like grain, coal, or scrap metal. Modern systems help them do it faster and safer.”

– Wes Domine, Thern Engineer

Myths About Modern Systems

Some operators hesitate to upgrade, believing older systems are “good enough.” However, this mindset can cost more in the long run.

- Myth: If it’s not broken, don’t fix it. Upgrades aren’t just about replacing old equipment; they’re about improving safety, cutting downtime, and future-proofing your operation.

- Myth: Modern systems are too expensive. While there’s an upfront cost, the savings in maintenance and improved efficiency make modern systems a smart investment for many years.

Why Choose Thern?

Thern’s barge positioning systems go beyond solving problems—they redefine how work gets done.

- Built for Tough Jobs: Direct-drive technology ensures reliability in the harshest environments.

- Custom Solutions: Every system is designed for your unique challenges.

- Proven Results: With decades of experience, Thern is the trusted name in barge positioning and material handling.

Are You Ready to Upgrade?

If your barge positioning system is causing delays, increasing risks, or costing too much in repairs, it’s time to rethink your approach. Modern systems aren’t just an upgrade—they’re the future of efficient, safe operations.

At Thern, we’re here to help you transition seamlessly. Contact us today to learn how our systems can work for you.

If you liked this post, you may also enjoy Thern Barge Positioning System: Power Meets Precision