What is wastewater treatment?

The wastewater treatment process removes the contaminants from the wastewater and converts it into an element that can be returned to the water cycle with minimum environmental impact. Water can carry harmful diseases and bacteria, making it important for it to undergo this treatment before it is returned to homes and businesses.

Wastewater is classified as used water from any combination of domestic, industrial, commercial, agricultural activities, surface runoff, or stormwater.

How does the wastewater treatment process work?

1. Travel

The wastewater travels through the large main sewer system underground to the wastewater treatment plant. As it reaches the plant, the water will be screened to remove any large items or debris from the sewage.

2. Preliminary Wastewater Treatment

At this stage, the sewage is forced through the grit chamber. Water makes its way from large screens to small screens, removing objects as small as a match.

3. Grit Removal

The water is then pumped into sedimentation tanks to separate the components of the sewage even further. This removes all remaining grit from the water to be disposed of as it cannot be reused due to high contamination.

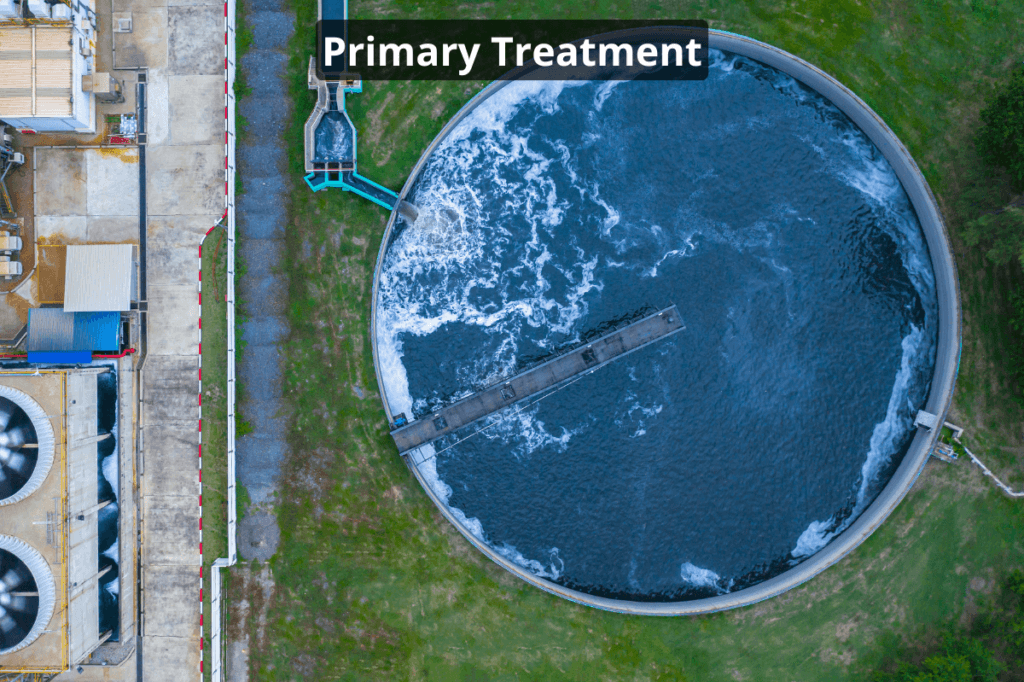

4. Primary Treatment

The water flows into primary settling tanks and is guided toward the hopper at the base of the tank. During this, the hopper arm moves around the edge of the tank. This allows for the treated water to move towards the edges and the sedimentation to flow and settle at the bottom of the tank.

5. Secondary Treatment (biological stage)

The wastewater treatment plant will use bacteria to consume contaminants, carbon, phosphorous and biodegradable organics. This will turn into sludge. Excess sludge is pumped out and moved to the digestion tanks for further treatment before the water enters the settling tanks.

Digestion Tanks: Sludge is heated and mixed, producing biogas. Wastewater treatment plants can reuse this biogas for electrical and thermal energy production. Water is then separated from the sludge and taken back for further treatment.

7. Disposal of sludge

All of the sludge gathered is disposed of in a sanitary landfill. After about a month, the sludge will be dried out enough to be used for agricultural purposes, such as fertilizing industrial crops.

8. Disinfection and Deep Inspection

The final step: The treatment plant undergoes a thorough inspection to analyze the contamination level. They make sure the treated water is acceptable to the highest standards. If the water passes this inspection it can be reused for domestic or industrial purposes.

For disinfection, treated water (also known as effluent) is sent through a chamber or series of reservoirs to allow sufficient time for chemicals or light to kill bad microorganisms that have not been removed. This effluent is now called ‘reclaimed water’ and is released back into the environment for beneficial purposes.

Wastewater treatment plants must reach a certain quality standard at the end of this process. To have this quality, they must ensure they stay up to date on maintenance and equipment. This equipment can be heavy and hard to maneuver.

Maintenance Tools: The Key to High-Quality Wastewater Treatment

Every stage of wastewater treatment—grit removal, sludge processing, and disinfection—relies on precise, reliable equipment. When maintenance falls behind, operations slow, water quality suffers, and costly downtime becomes inevitable.

Handling heavy equipment like pumps, UV panels, and sludge carts is tough enough without the added frustration of outdated tools. Tight spaces, hard-to-reach areas, and corrosion-prone environments only make things harder.

Whether you need stationary reliability or portable versatility—Thern’s innovative lifting solutions are designed to make maintenance smarter, safer, and more efficient:

- Davit Cranes: Streamline pump and UV panel maintenance with 360° rotation, extended reach, and multiple operation options.

- Custom Winches: From cart-positioning systems to bar screen winches, Thern designs solutions tailored to your facility’s unique challenges.

- The Commander AL: Our new portable aluminum davit crane combines lightweight portability with heavy-duty strength. With a lifting capacity of 1,200 lbs and corrosion-resistant construction, it’s the perfect solution for wastewater plants that need flexibility in tight spaces or harsh environments. Watch a firsthand review from a wastewater operator here:

When you maintain your plant’s equipment, every step of the treatment process works seamlessly—ensuring safe, high-quality water every time.

Ready to leave the heavy lifting to us?

Explore Thern’s solutions today and see how tools like the Commander AL can transform your maintenance workflow.

This post was originally published on June 11, 2020, and updated with the latest information on January 27, 2025.