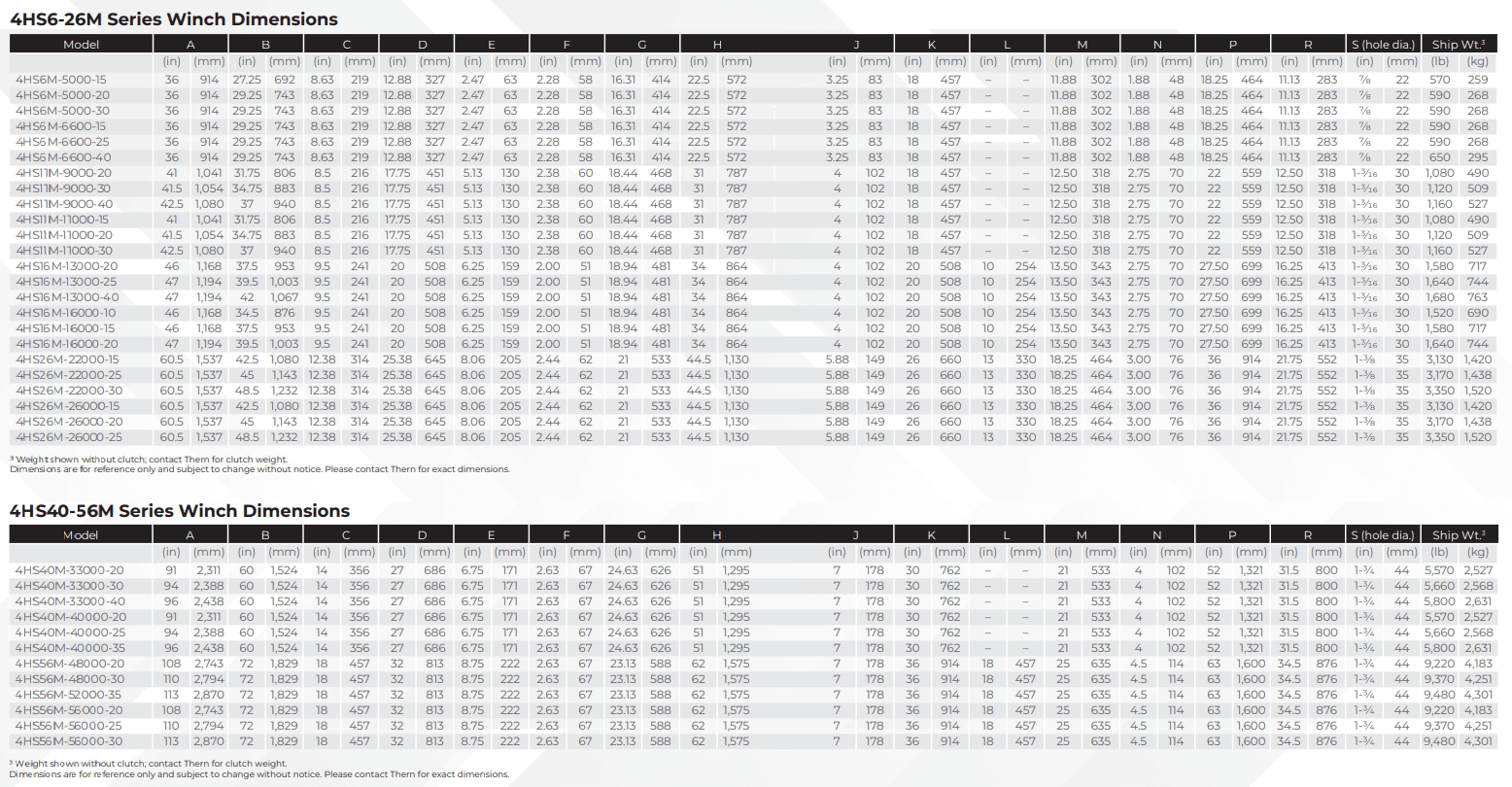

4HS Helical Spur Serie

Capacidad de 5,000 a 26,000 libras

Los cabrestantes eléctricos de la serie 4HS de Thern cuentan con una combinación de engranajes helicoidales/cónicos o helicoidales/paralelos y rectos que hacen que estos cabrestantes sean ideales para aplicaciones que requieren largas distancias de recorrido y velocidades de línea más rápidas.

Hechos rápidos

- Rodamientos de rodillos con brida

- Tambor de acero soldado

- Eje de tambor de acero extendido

- Conjuntos de cables metálicos

- Motor montado en brida

- Freno de disco del motor de retención de carga

- Engranaje de doble etapa

- Cumplimiento AMSE

- Garantía limitada de 2 años

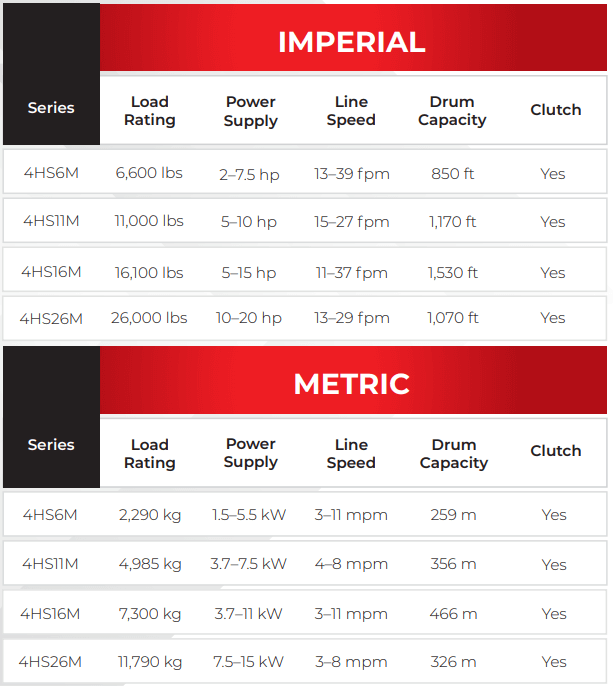

Modelos de serie

- 4HS6M

- 4HS11M

- 4HS16M

- 4HS26M

- 4HS40M

- 4HS56M

¿Necesita una cotización?

Si no está seguro de qué producto necesita y desea una cotización, complete un formulario de solicitud.

4HS Series — Modelo 4HS16M Cabrestante eléctrico de servicio pesado.

Flange Mounted Motor

Motor is a 230 or 460 volt, 3 phase motor, 60 cycle, IP 54*, TEFC severe duty, reversible, class B or F insulated, continuous duty brake motor. Standard motors comply with relevant standards including NEMA, MG1, ANSI, CSA, IEC1 and ABS.

Load Holding Motor Disc Brake

Brake is spring set, electrically released for positive load control.

Dual Stage Gearing

Gearing is comprised of a worm or helical/worm and spur gears, making winches well suited for applications requiring secure load control and accurate positioning. The heat-treated worm or helical/worm gear set provides improved durability and operates in an oil bath, enclosed in a high strength cast iron gear case, SAE class 30. Double-lip oil seals keep oil in and contaminants out. Large capacity bearings ensure long life. Speed reducers meet AGMA standards. Guarded, heat treated spur gearing provides secondary reduction. Grease zerks allow for easy lubrication.

Flange Style Roller Bearing

Bearings are self-aligning with cast housing to maintain smooth drum rotation.

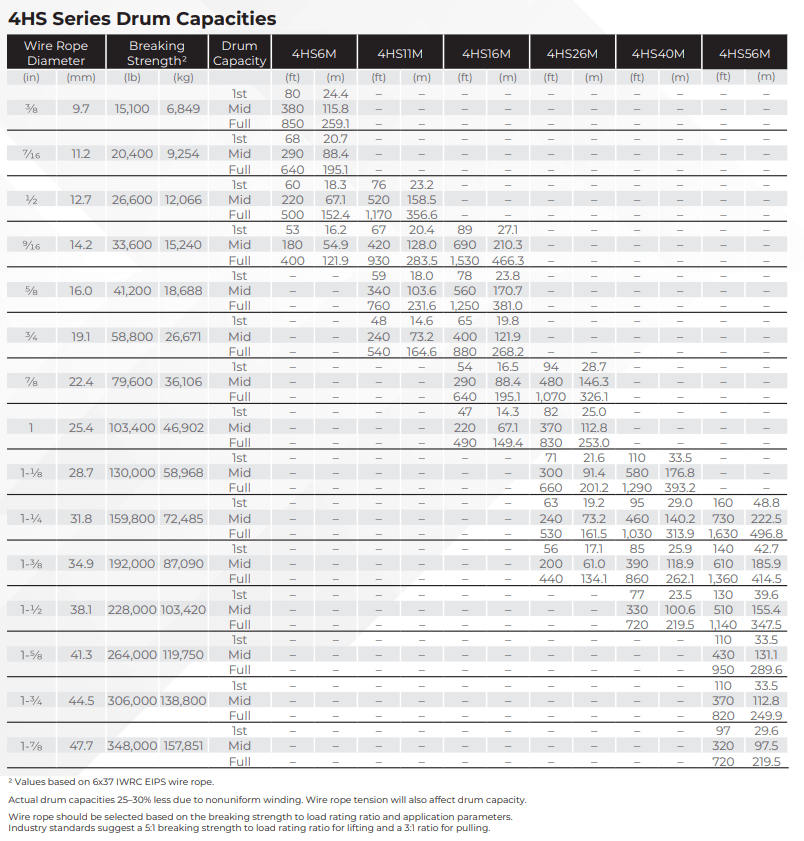

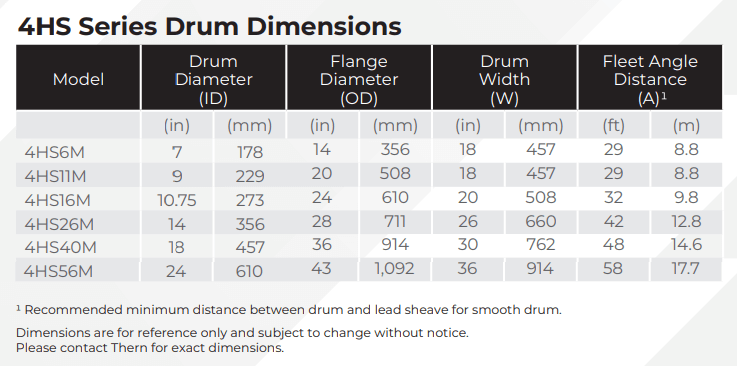

Welded Steel Drum

Drum has outside flange anchors, which allow for uniform winding and helps to extend life of wire rope. Anchors allow cable to be over wound or under wound from either side of the drum.

Extended Steel Drum Shaft

Captures both ends in a fabricated steel frame for optimal strength and security.

Wire Rope Assemblies

Sold separately per customer request.

AMSE B30.7 Compliance

Please contact the factory.

Two-Year Warranty

Industry-leading two-year “Move It With Confidence” limited warranty.

Vertical Lead Block

The Redline Series is used to change the direction of the rope, so the winch can be mounted in a convenient location and the Redline Lead Block will control the path of the rope to avoid obstacles, reduce hazard, and improve rope wear. Vertical Lead Block Series

Drum Modifications

Available modifications include grooved drums, multiple compartment drums and modified drum widths and diameters.

Jaw Clutch

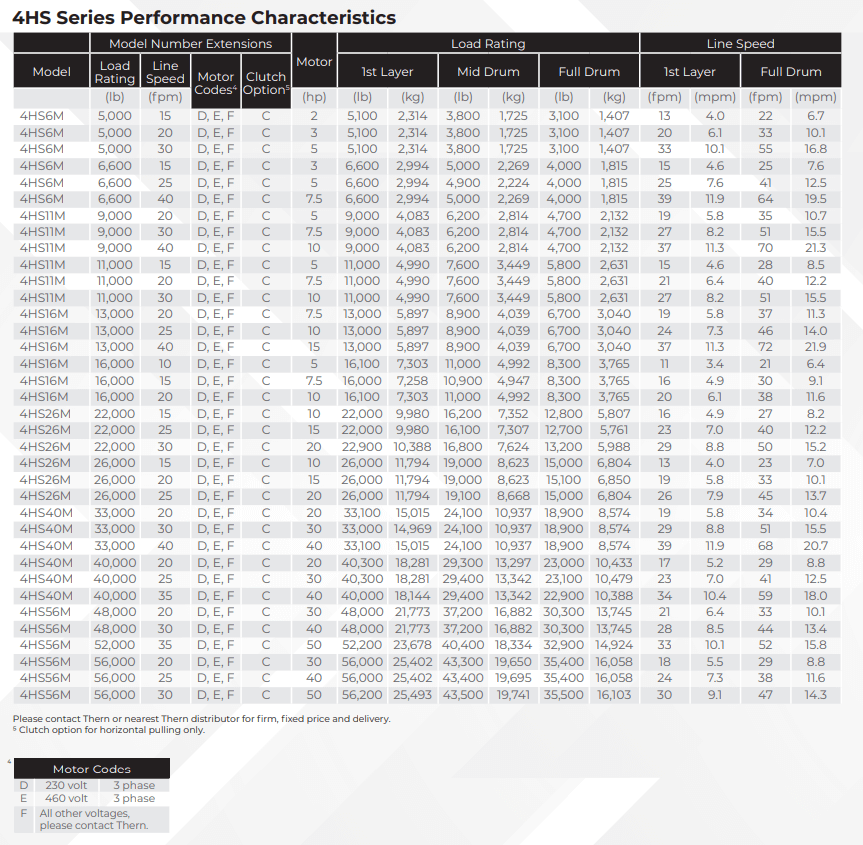

Clutch is manually operated and disengages for rapid payout of wire rope when not under load. Adjustable drag brake on the drum prevents over-spooling during payout. Clutch option is for horizontal pulling only.

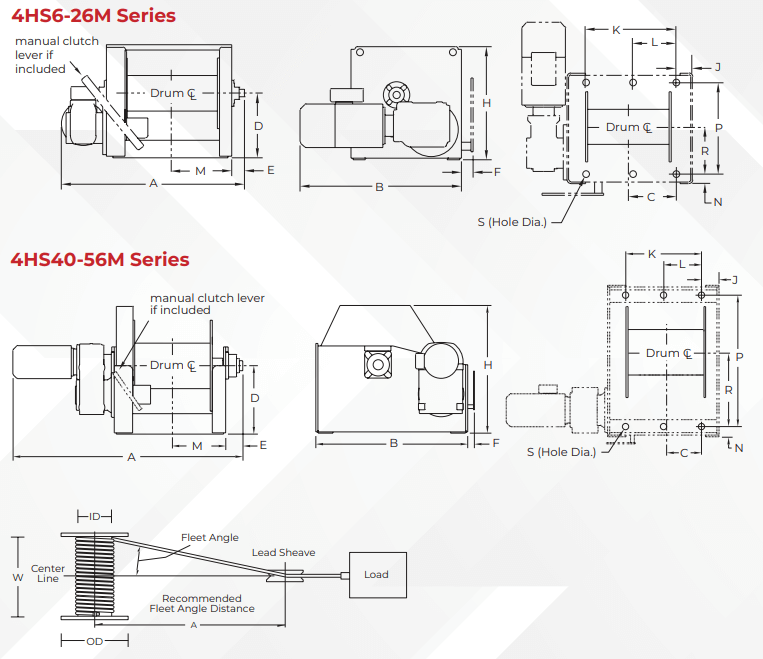

Mounting Options

Available options include base, wall or under hung installation.

Cable Pressure Bars

Apply pressure to drum and wire rope to help maintain uniform winding.

Light Switches

Provide secondary shut-off for load travel in one or two directions.

Motors

Include air or hydraulic, voltage or phase changes, IP 55 or 65, class F or H insulated and multi-speed operation.

Duty Ratings

Include IEEE 45 marine duty, tropical duty, severe duty and explosion proof ratings.

Brakes

Include over-speed, caliper style, band, and more. Please contact the factory.

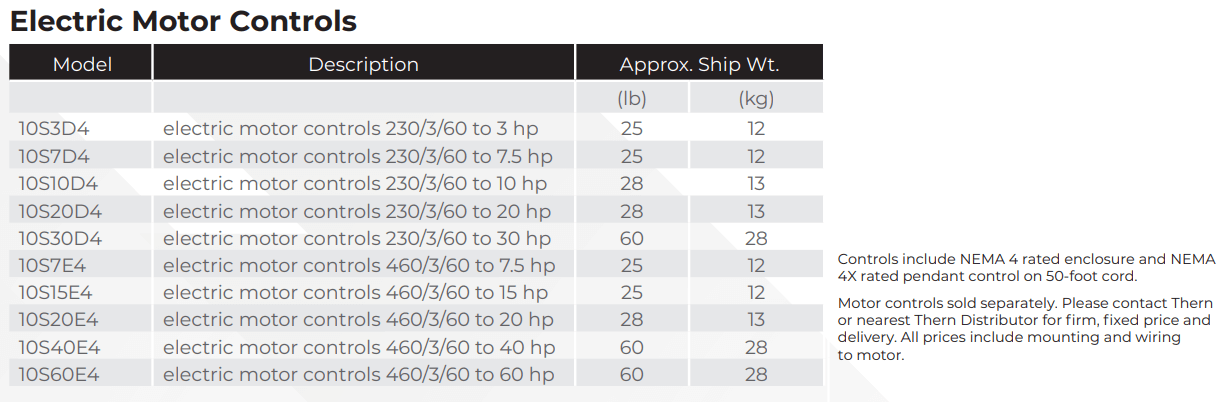

Controls

Available in a wide range of standard and custom configurations for single or variable speed.

Corrosion Resistant Finishes

For operation in harsh or hazardous environments.

Manual Overrides

For winch operation in power loss situations.

Owner’s Manual

Product Sheet

4HS Series Product Sheet (PS4HS-A-0221)