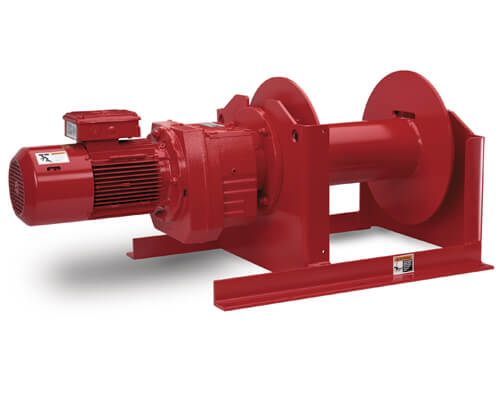

4HPF Helical Parallel Série

Capacité de 2 000 à 25 000 lb

Les treuils électriques Thern de la série 4HPF sont dotés d’un engrenage hélicoïdal/parallèle à haut rendement, ce qui les rend idéaux pour les applications nécessitant de longues distances de déplacement et des vitesses de ligne plus rapides.

Faits rapides

- Roulements à rouleaux à bride

- Fût en acier soudé

- Arbre de tambour rallongé en acier massif

- Assemblages de câbles métalliques

- Moteur monté sur bride

- Frein à disque du moteur de maintien de charge

- Réducteurs à entraînement direct

- Conformité AMSE

- Garantie limitée de 2 ans

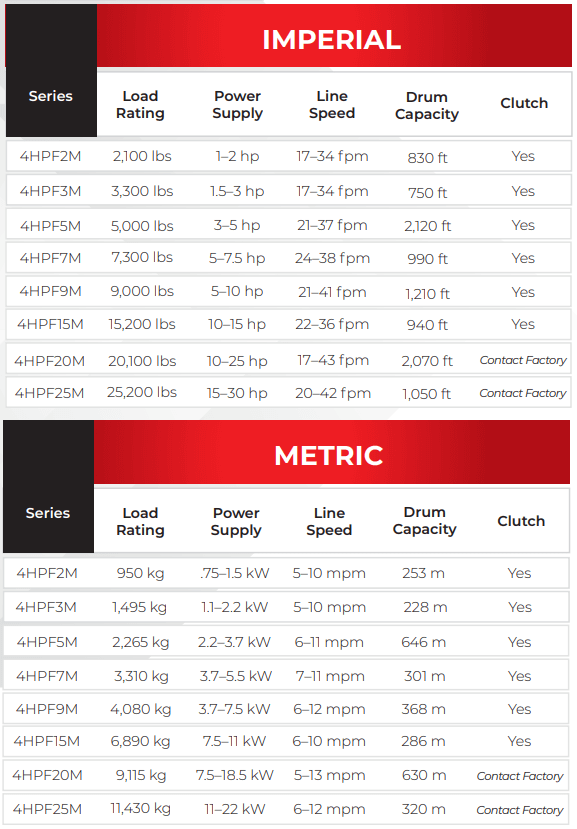

Modèles de série

- 4HPF2M

- 4HPF3M

- 4HPF5M

- 4HPF7M

- 4HPF9M

- 4HPF15M

- 4HPF20M

- 4HPF25M

Besoin d'un devis ?

Si vous n’êtes pas sûr du produit dont vous avez besoin et souhaitez un devis, veuillez remplir un formulaire de demande.

4HPF Series — Modèle 4HPF Helical/Parallel Treuil électrique robuste.

Flange Mounted Motor

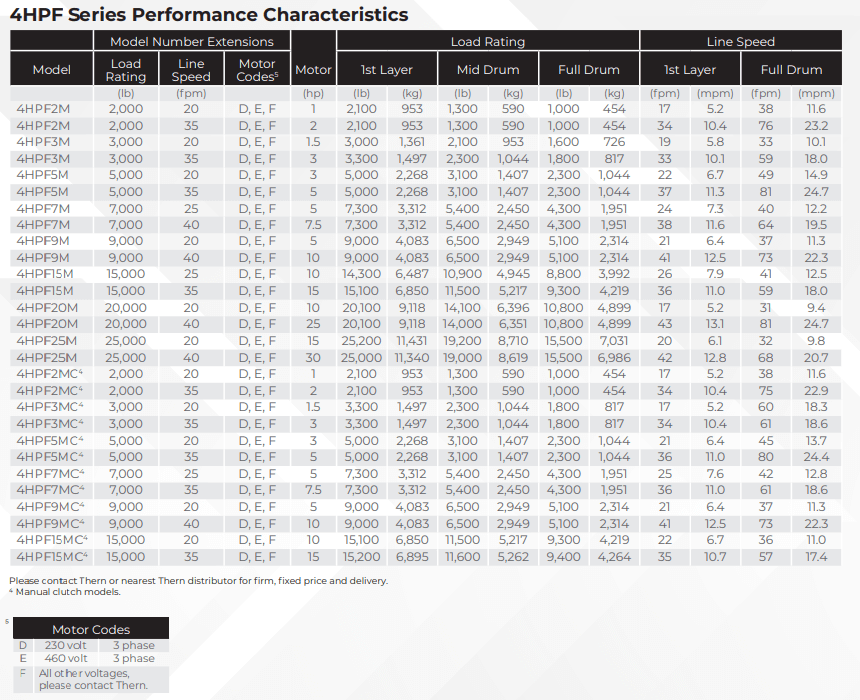

Motor is a 230 or 460 volt, 3 phase motor, 60 cycle, IP 54*, TEFC severe duty, reversible, class B or F insulated, continuous duty brake motor. Standard motors comply with relevant standards including NEMA, MG1, ANSI, CSA, IEC1 and ABS.

Load Holding Motor Disc Brake

Brake is spring set, electrically released for positive load control.

Direct Drive Gear Reducer

Reducer is comprised of helical/worm gears and delivers lower efficiencies from 65% to 76% making winches well suited or applications requiring secure load control and accurate positioning. The heat-treated helical/worm gear set provides improved durability and operates in an oil bath, enclosed in a high strength cast iron gear case, SAE class 30. Double lip oil seals keep oil in and contaminants out. Large capacity bearings ensure long life. Speed reducers meet AGMA standards.

Flange Style Roller Bearing

Bearings are self-aligning with cast housing to maintain smooth drum rotation.

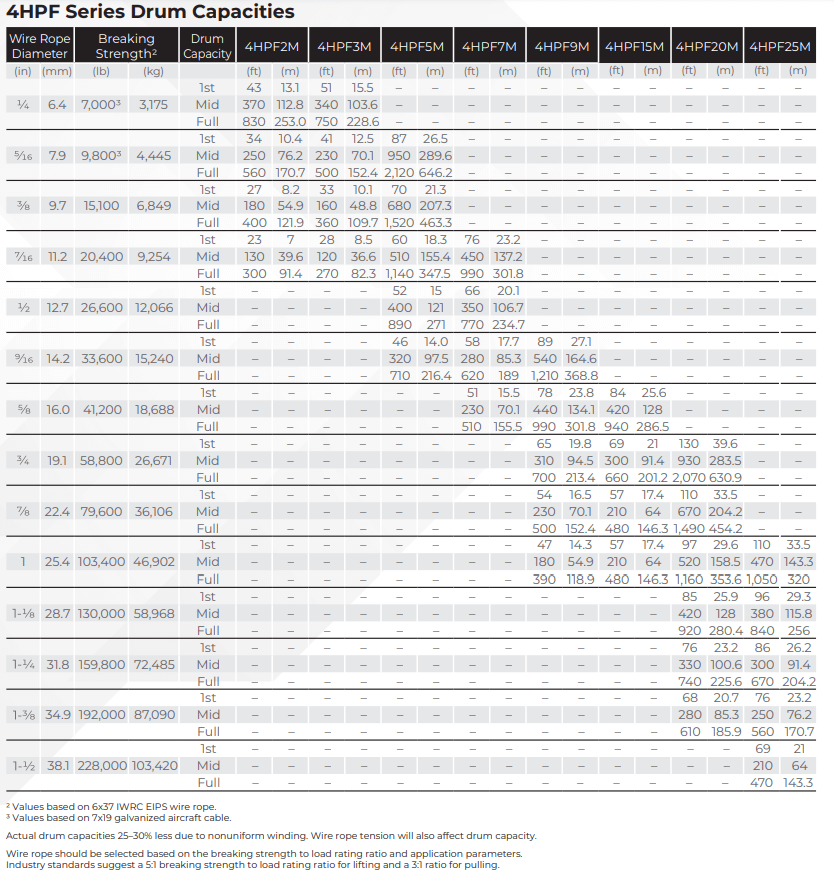

Welded Steel Drum

Drum has outside flange anchors, which allow for uniform winding and helps to extend life of wire rope. Anchors allow cable to be over wound or under wound from either side of the drum.

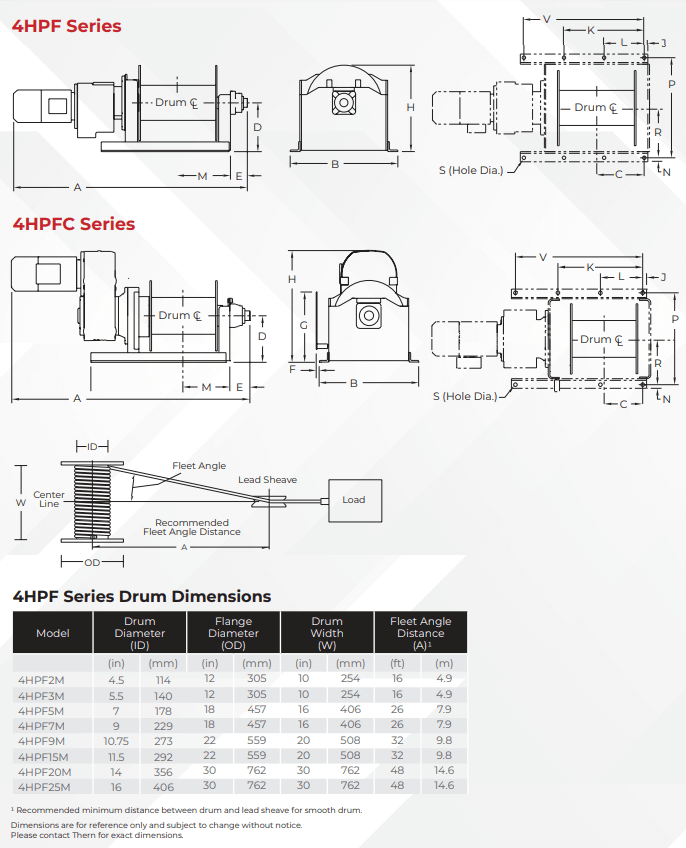

Extended Steel Drum Shaft

Captures both ends in a fabricated steel frame for optimal strength and security.

Wire Rope Assemblies

Sold separately per customer request.

AMSE B30.7 Compliance

Please contact the factory.

Two-Year Warranty

Industry-leading two-year “Move It With Confidence” limited warranty.

Vertical Lead Block

The Redline Series is used to change the direction of the rope, so the winch can be mounted in a convenient location and the Redline Lead Block will control the path of the rope to avoid obstacles, reduce hazard, and improve rope wear. Vertical Lead Block Series

Drum Modifications

Available modifications include grooved drums, multiple compartment drums and modified drum widths and diameters.

Jaw Clutch

Clutch is manually operated and disengages for rapid payout of wire rope when not under load. Adjustable drag brake on the drum prevents over-spooling during payout. Clutch option is for horizontal pulling only.

Mounting Options

Available options include base, wall or under hung installation.

Cable Pressure Bars

Apply pressure to drum and wire rope to help maintain uniform winding.

Light Switches

Provide secondary shut-off for load travel in one or two directions.

Motors

Include air or hydraulic, voltage or phase changes, IP 55 or 65, class F or H insulated and multi-speed operation.

Duty Ratings

Include IEEE 45 marine duty, tropical duty, severe duty and explosion proof ratings.

Brakes

Include over-speed, caliper style, band, and more. Please contact the factory.

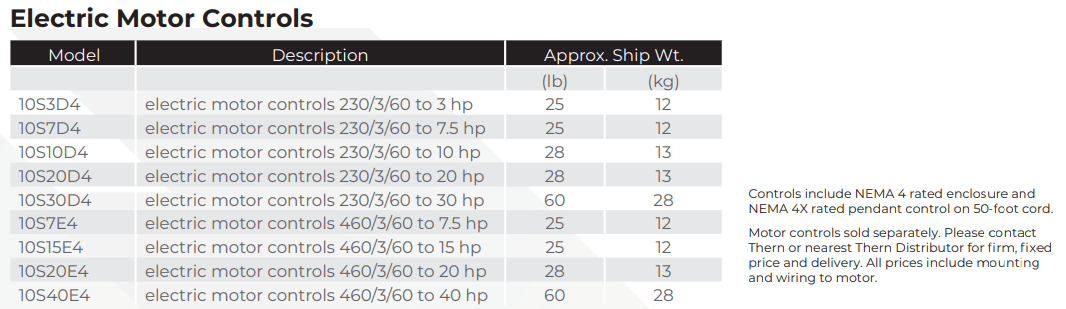

Controls

Available in a wide range of standard and custom configurations for single or variable speed.

Corrosion Resistant Finishes

For operation in harsh or hazardous environments.

Manual Overrides

For winch operation in power loss situations.

Owner’s Manual

4HPF, 4HWF, 4HBP, 4HBN (A7944D)

Product Sheet

4HPF Product Sheet (PS4HPF-A-0221)